An engine for the Motor Cutter

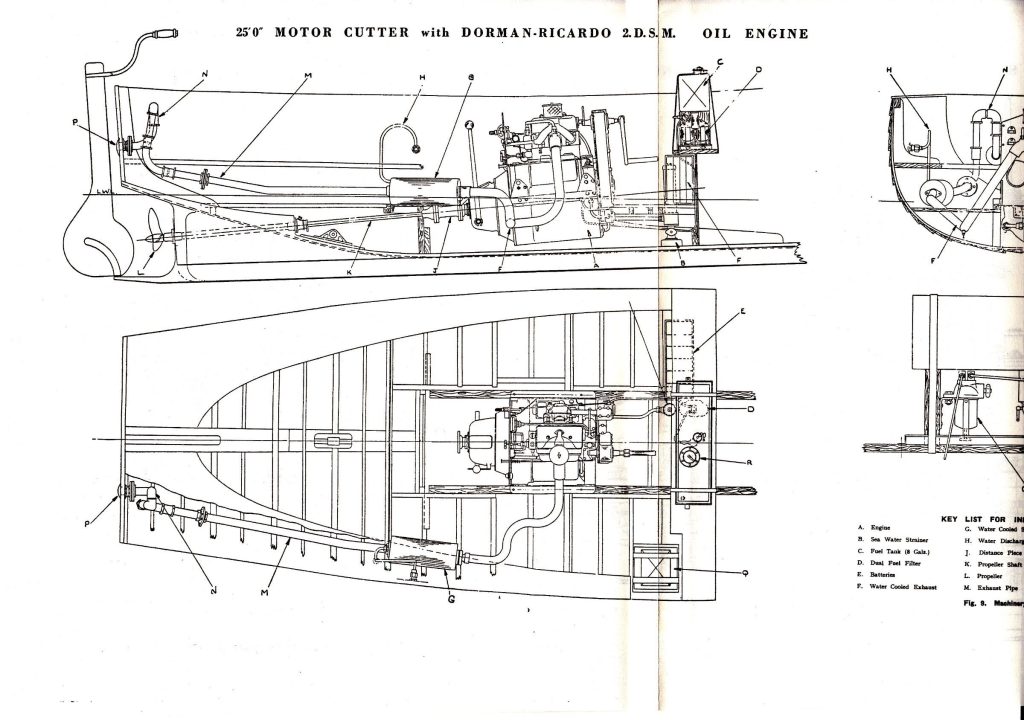

When originally designed it was intended that the Motor Cutter would be fitted with a ‘small’ diesel (compression-ignition) or ‘oil’ engine of a make and type then commercially available. Engines of about 10-12 hp were listed with types from Dorman, Ferry and Fowler shown on the plans. From other records it appears that the Admiralty or the Ministry of Supply purchased engines in batches and issued them to boat builders who had contracts to build the boats. No petrol engines were used in standard Motor Cutters.

The almost universally adopted engine was the Dorman-Ricardo 2DSM that was made by W.H.Dorman &Co of Stafford, England. Dorman was a renowned engineering company and produced a wide range of oil engines for many markets and applications, with a large proportion going to export markets. A history of W. H. Dorman can be found here. http://www.dorman-association.org

We found an engine!

A chance conversation with a vintage engine collector and enthusiast lead to me being offered not just one complete and running Dorman 2DSM but also another partially dismantled engine – the deal was that I had to buy both, but hey, ho… Apparently both these engines had been doing service in a pair of sea cadet training vessels somewhere on the South Coast but some new regulation deemed them to be too low-powered in a training vessel and they were removed and sold on. We hired a van and fetched both engines and brought them to the yard in Pembrokeshire.

Testing and preparing an engine

I must admit to being a bit in awe of the sheer weight of these engines; the specification states a dry weight of 1,050lbs (about 475kg) which by modern standards is truly enormous mass of cast iron for a power plant producing just 10hp. However, this explains why the boat has such long and deep engine bearers and the additional sawn frames to spread the engine’s weight over the relatively lightly built hull.

We had a day tinkering with the complete engine in the yard. Valve clearances were checked and some oil poured over the valve gear and a fuel supply rigged up and pump and injectors were bled. A battery was hooked up and after a bit of cranking we got it to start.

Although the engines looked relatively complete there was no control panel, proper instruments and crucially, no battery charging dynamo supplied or fitted. Using the drawings in the manuals and parts list I designed and made a control panel and mounting frame and sourced suitable instruments and controls and fabricated operating rods for speed control and oil filter actuator. The dynamo was a problem as the original CAV type was very elusive but eventually I found a Lucas unit with similar characteristics and a low enough cutting-in speed. A contact of mine machined me an adaptor hub and I made mounting straps to hold it in place.

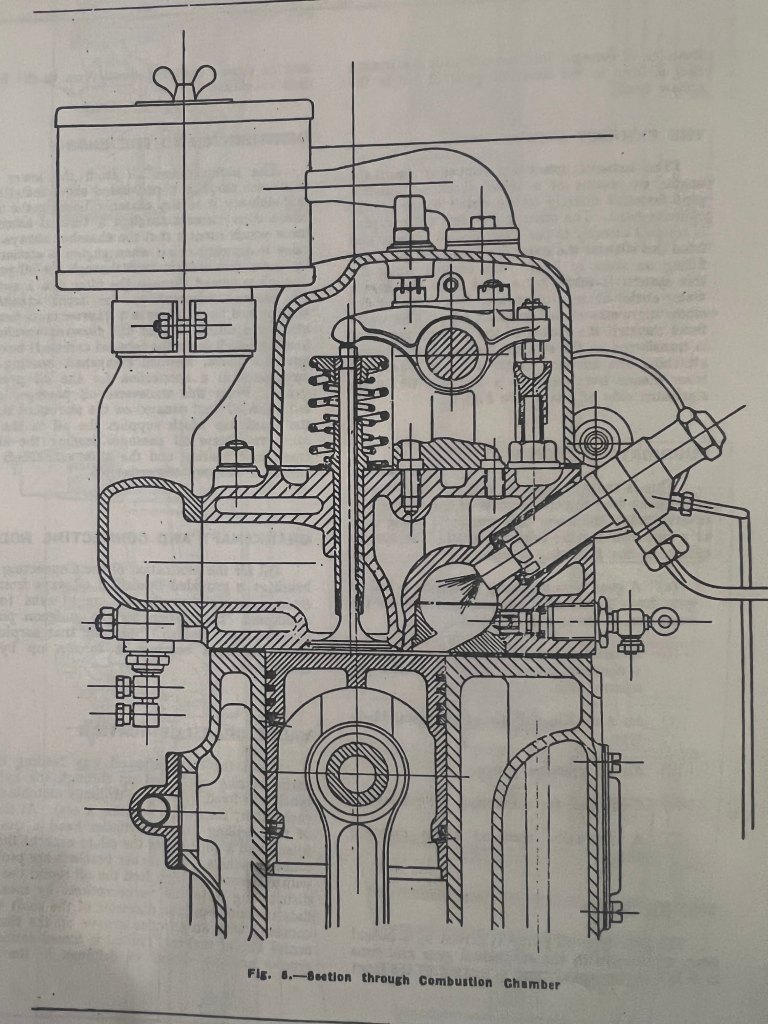

Further testing followed which showed a problem with poor starting and erratic low speed running. This engine is of course of indirect injection and has Ricardo Comet swirl chambers (also known as pre-combustion chambers) in the head which at the time was cutting edge diesel engine technology. The brainchild of brilliant engineer Harry Ricardo https://en.wikipedia.org/wiki/Harry_Ricardo which paved the way for higher speed and better fuel efficiency in CI engines that are still in use to this day in some light weight diesel engines.

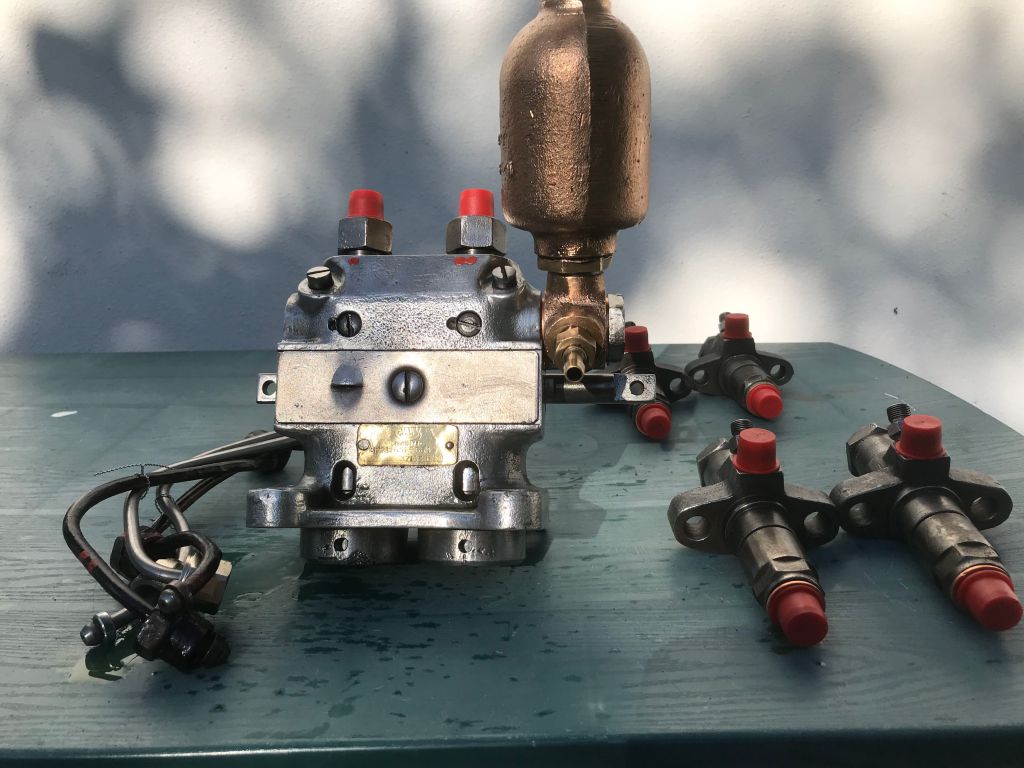

The drawback with the swirl or pre-combustion chambers are that they need pre-heating in order to start and on this engine an electric glow plug is fitted to each via a threaded adapter in the cylinder head. Both the plugs fitted had burnt away and replacements looked impossible to find. The solution was to make new adapters to fit ‘modern’ readily available plugs and I chose ones from a Land Rover engine that had the correct ‘reach’. Once fitted and wired these enabled the engine to start more smartly with minimal cranking. However, the poor running remained. I elected to have the injectors and pump serviced and after paying a huge bill (nearly as much as buying the engines!) I had two injectors with brand new delivery nozzles with correct opening pressure settings and a cleaned, tested and calibrated fuel pump and two new injector pipes. I also carried out a compression test on the engine and found the pressures and balance between cylinders to be good – so no immediate problems with piston rings or valve seating.

The engine was now built up after cleaning and painting. Unsure of the exact original colour I’ve painted it a Ruston grey that closely matched what I assumed was the Admiralty colour. There is also plenty of copper and brass to keep polished too. The engine was sheeted-up ready for installation in the boat.

Towards the end of 2024 I had the opportunity to get the Cutter moved from the boatyard where I was paying rent, to my own yard. We lifted her engine in first as we had the offer of the tele handler and then a truck with HIAB came and uplifted her for transport to my field. The HIAB operator did not have any spreaders so we placed a pair of stout timbers across the gunwales to stop her being crushed by the slings. We took all my blocks and timbers with us and set her down on a convenient flat concrete slab by the hedge.

Return to homepage http://clinkerboats.co.uk